1. Market Analysis

Hattiesburg housing demand drives development decisions.

| Average Rent | $900 - $1,100/mo |

| 1-Bedroom | $888 - $921/mo |

| 2-Bedroom | $1,083 - $1,101/mo |

| 3-Bedroom | $1,450/mo |

| Year-over-Year | +29% |

Rents are 48% below national average. Units must be right-sized to local rates.

| Median Home Price | $185K - $222K |

| YoY Appreciation | +6.5% |

| Days on Market | 50-74 days |

| vs National Avg | 40% lower |

| Forrest General Hospital | 3,100+ employees |

| Univ. of Southern Miss | 14,500 students |

| Camp Shelby | 2,200 + 60K annual visitors |

| William Carey University | ~5,000 students |

| Regions Financial | 500 employees |

These employers can tell us exactly what housing their workers need.

- Rents LOW (~$900/mo) - units must be affordable to build

- 67% renters = strong demand, but price-sensitive

- Young median age = workforce housing, not luxury

- Housing Authority waitlist CLOSED = unmet demand

Conclusion: Market supports workforce housing at moderate price points.

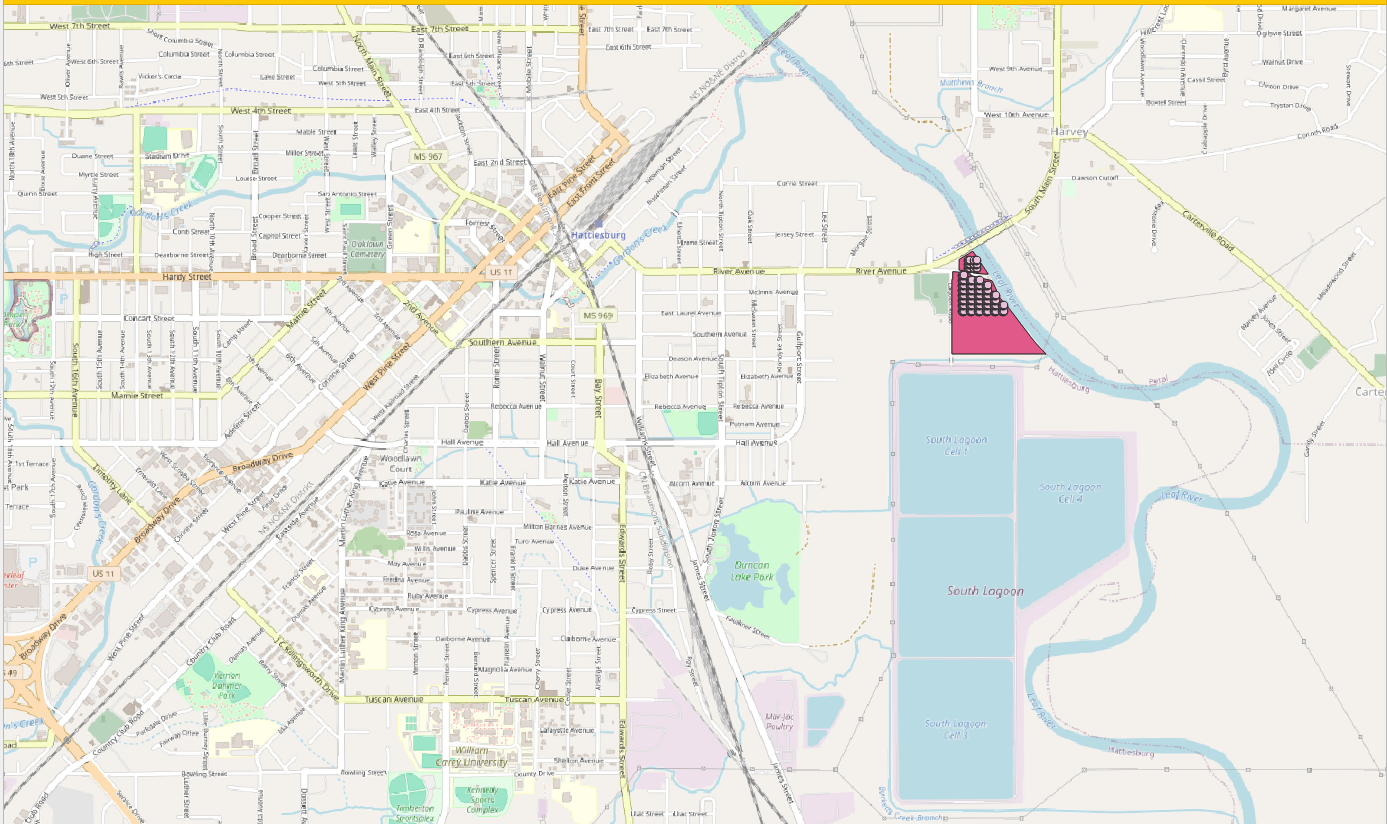

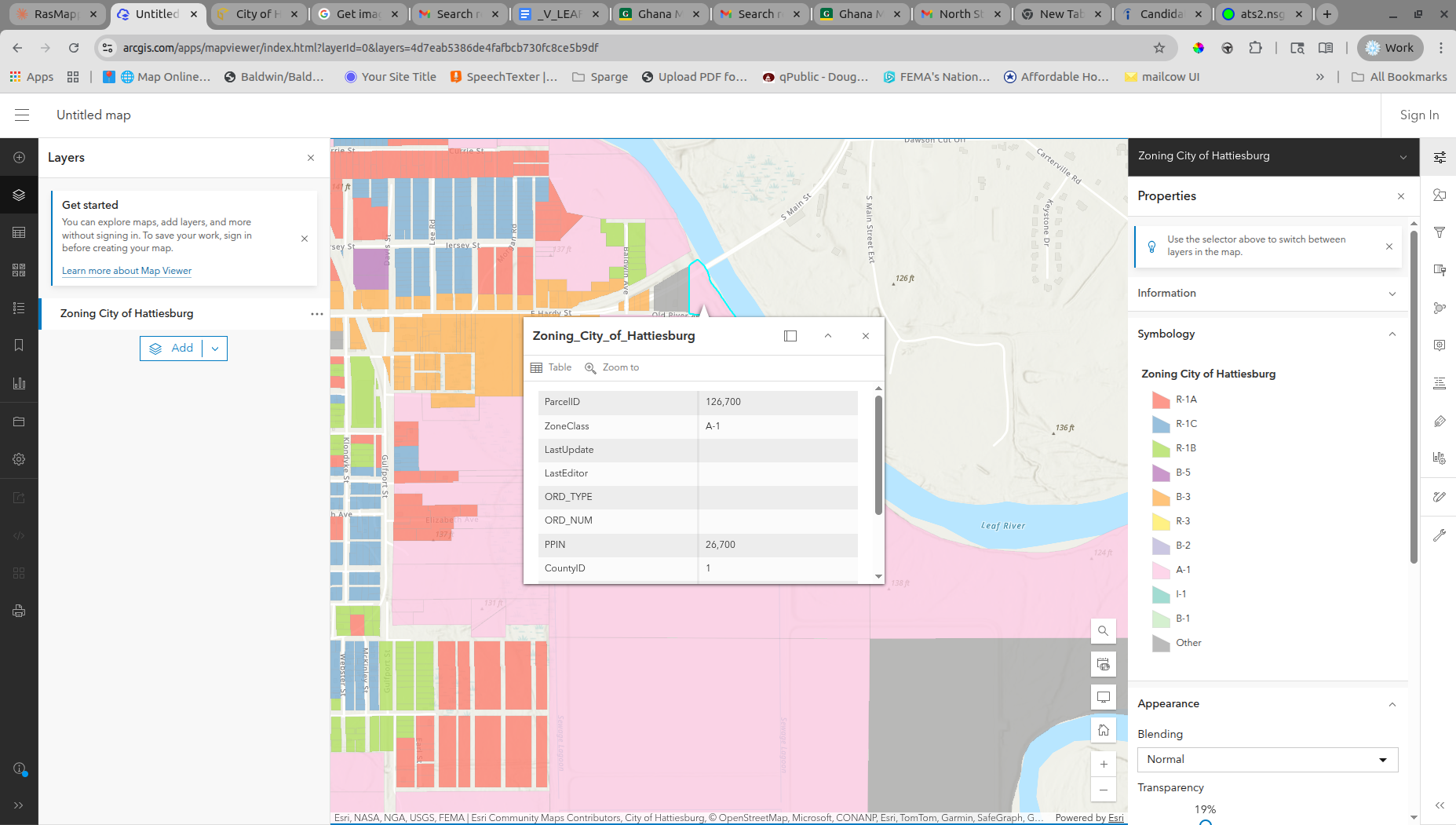

2. The Property

~30 acres across three parcels on the Leaf River.

Three Parcels

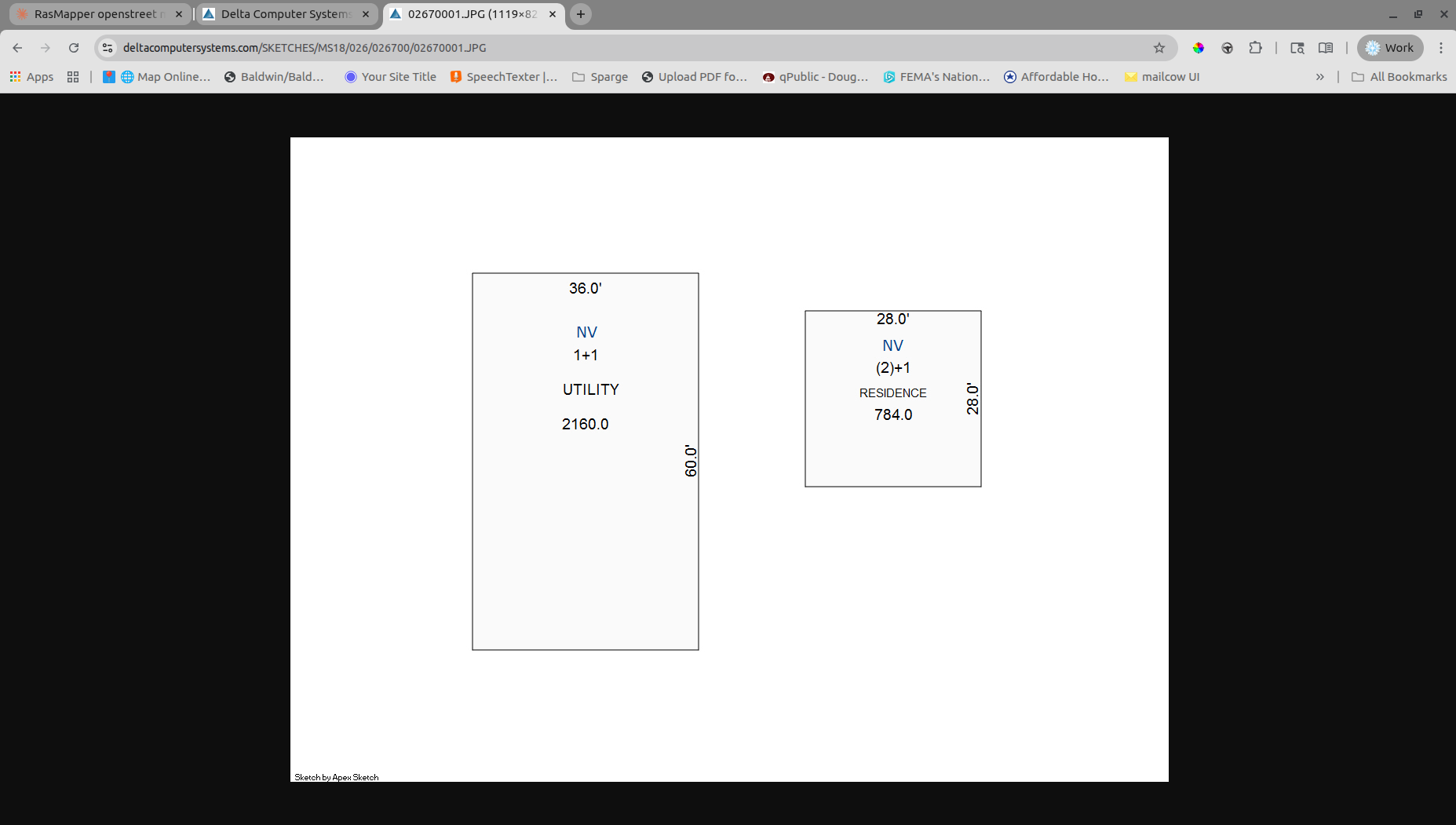

PPIN 26700

Montgomery

~3 acres, existing pad

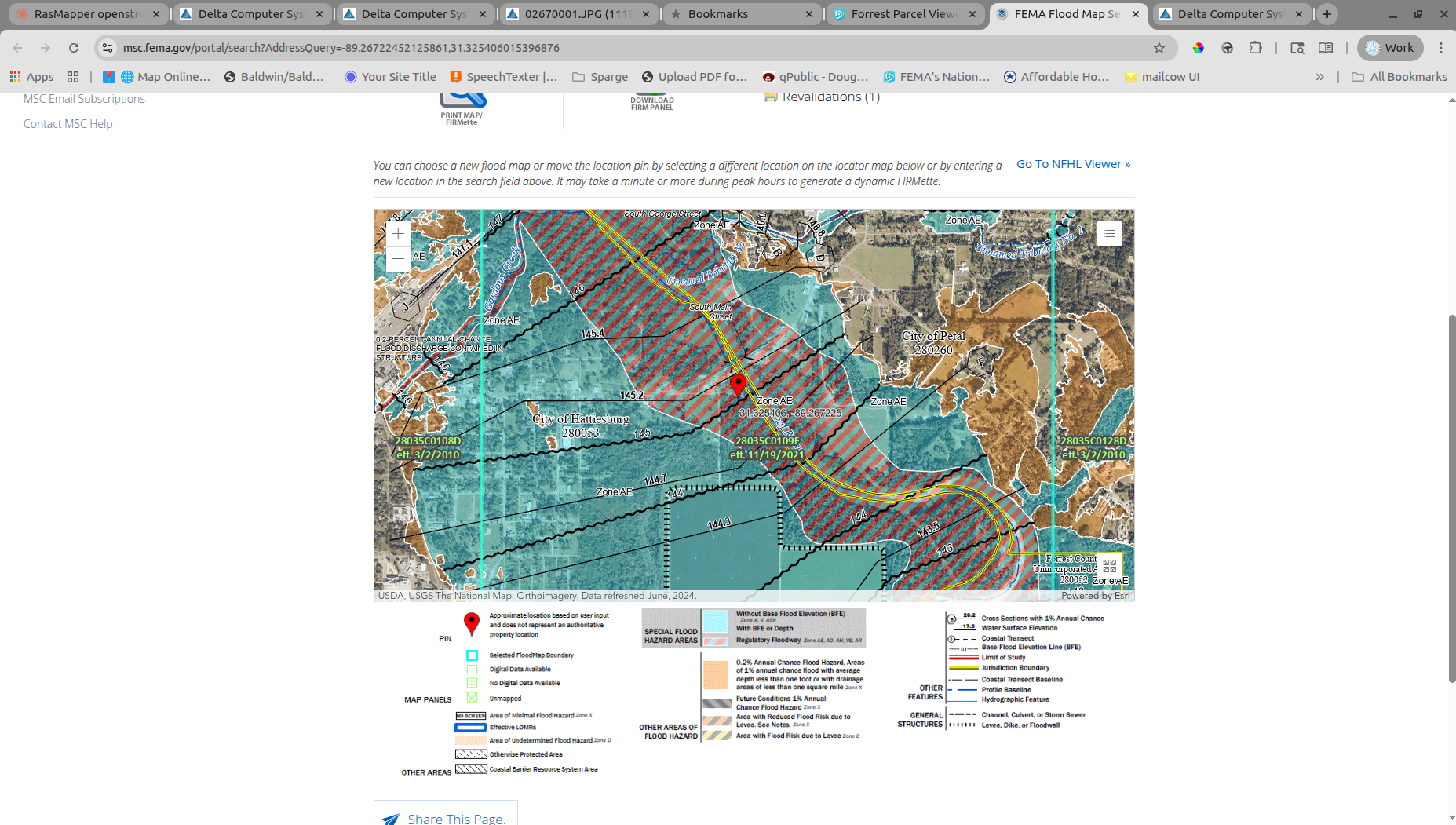

Zone AE - Flood

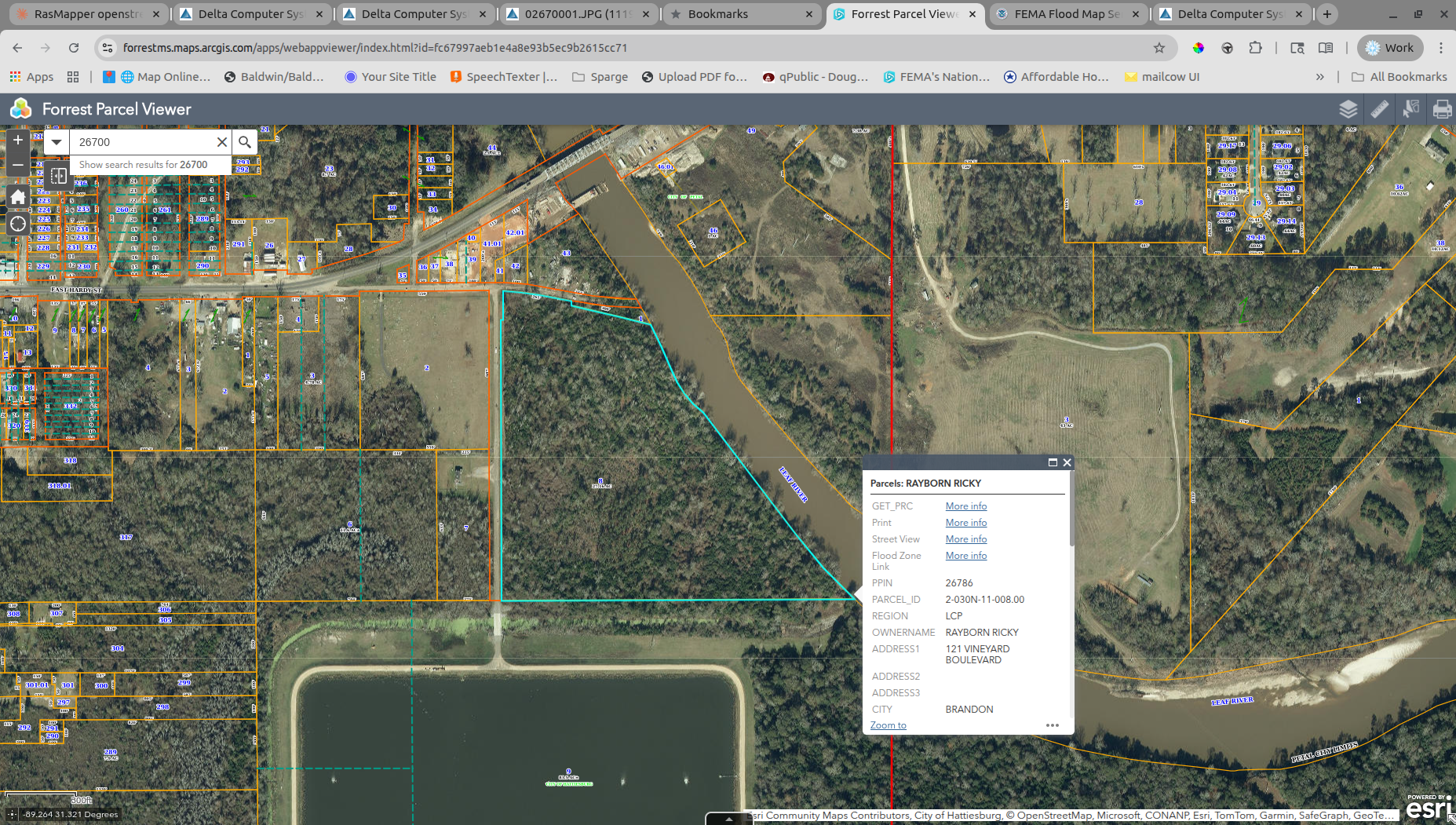

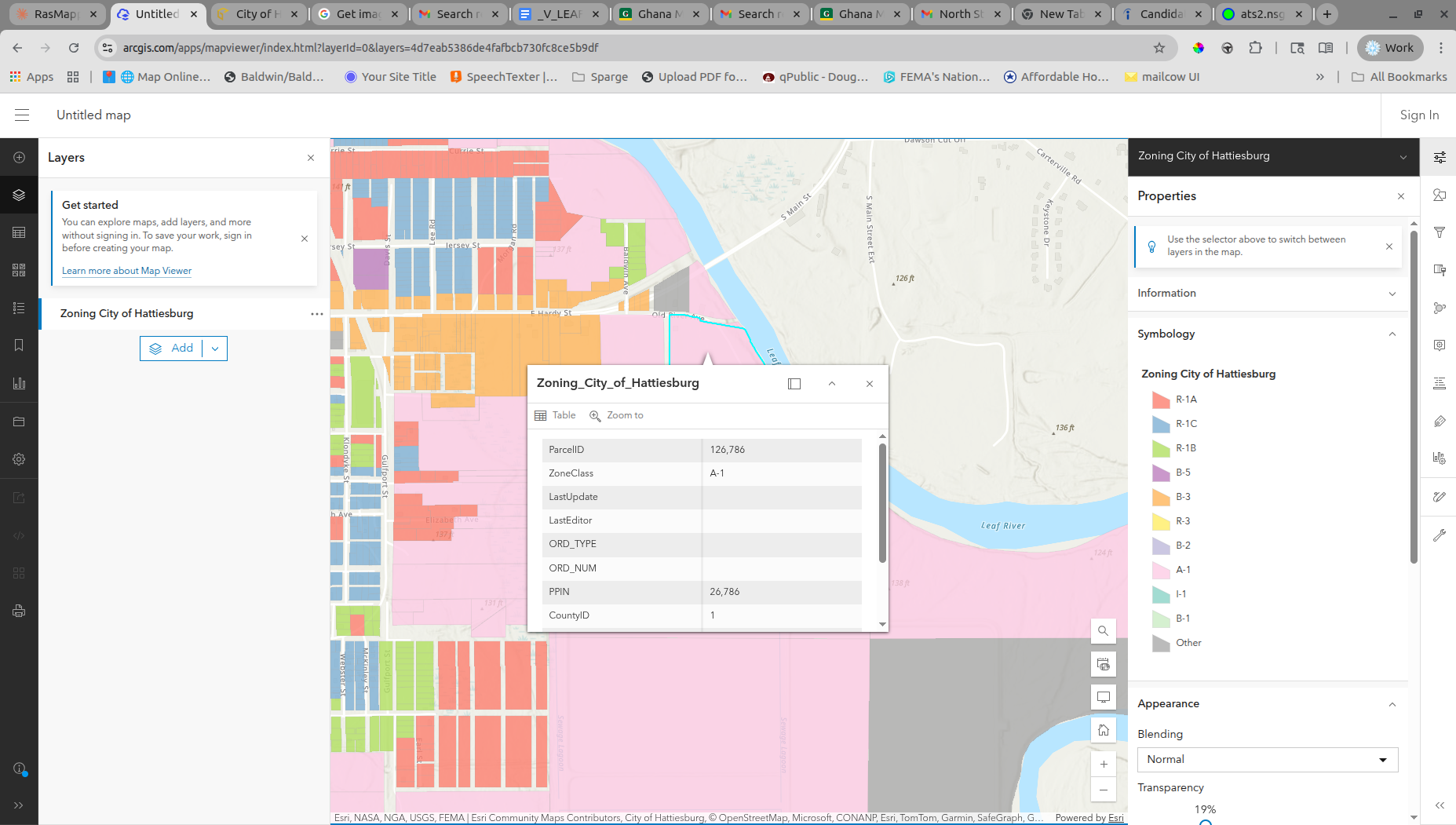

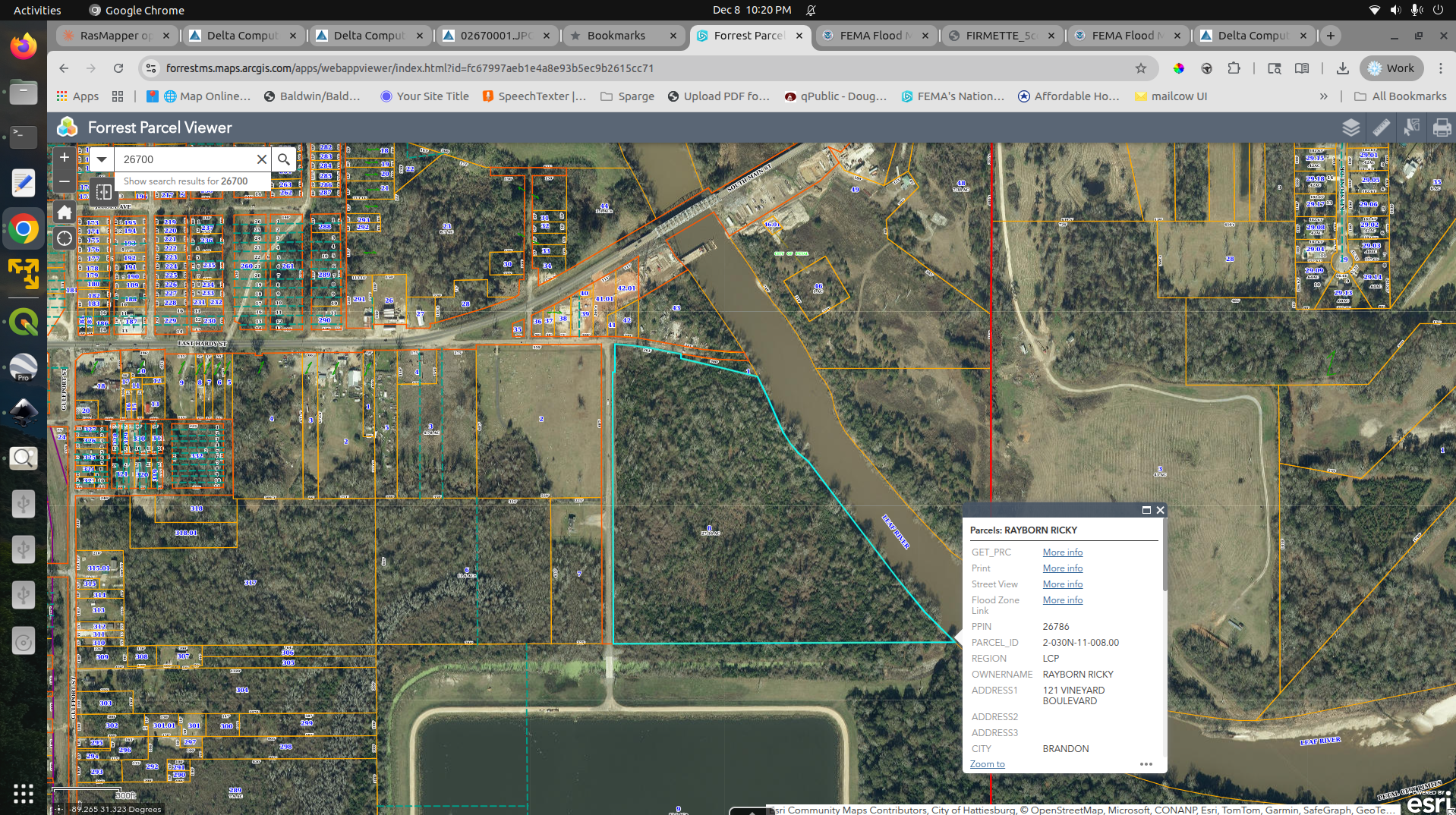

PPIN 26786

Rayborn

Large parcel, primary area

Mixed zones

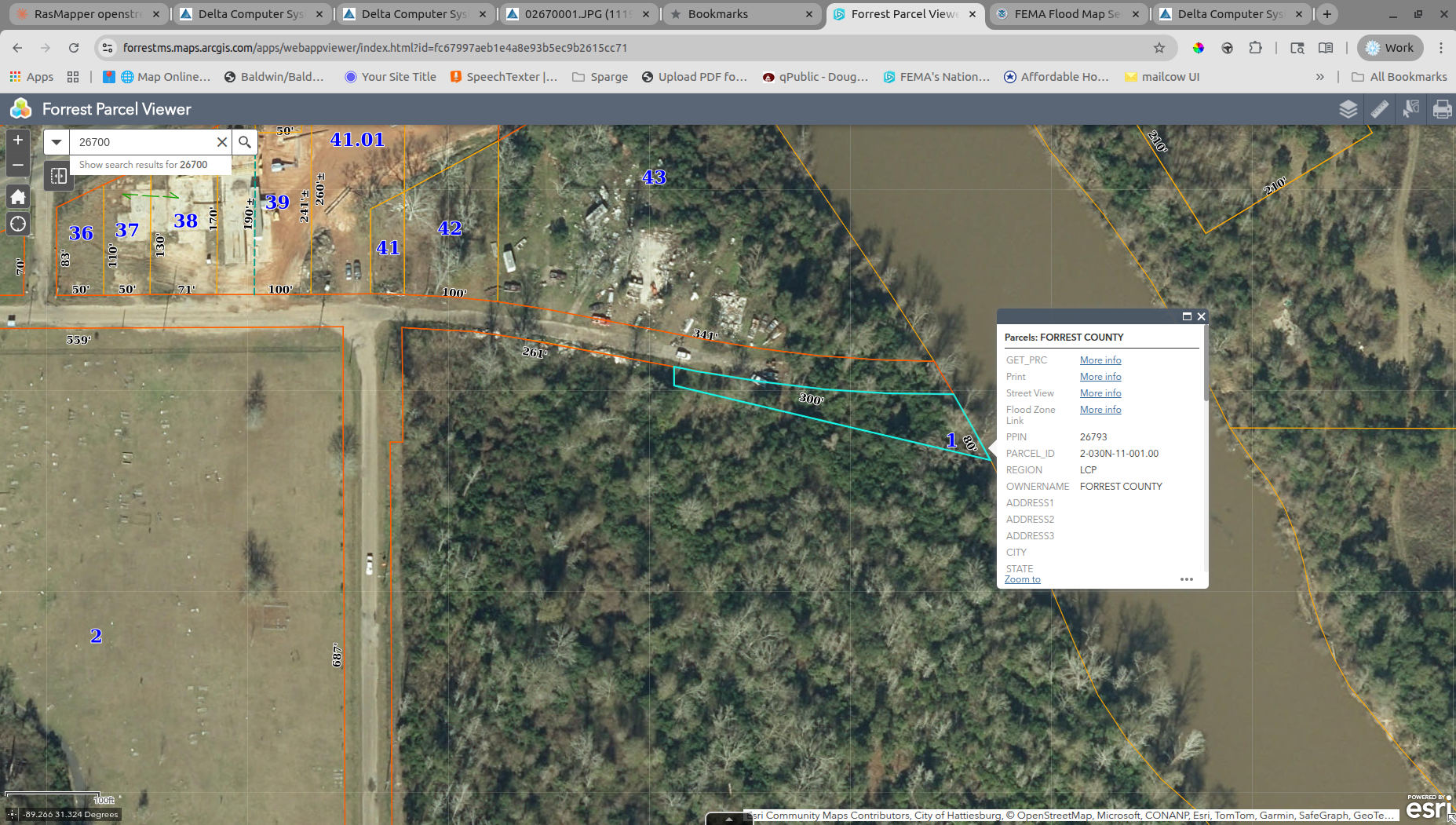

PPIN 26793

Forrest County

County-owned, strategic

Future opportunity

Front parcel: 253' × 390' with existing pad area.

Large parcel owned by Rayborn - primary development area.

Forrest County ownership creates future partnership opportunity.

Current A-1 zoning. Options: Rezone, conditional use, or PUD.

3. Development Strategy

Current thinking on parallel development tracks.

Front Parcel Development

Status: Waiting on Jill's HEC-RAS analysis (January 2025)

- Structure on piers in flood zone

- Restaurant, office, or promotional space

- Creates visibility, gauges market interest

Dependency: Requires No-Rise certification.

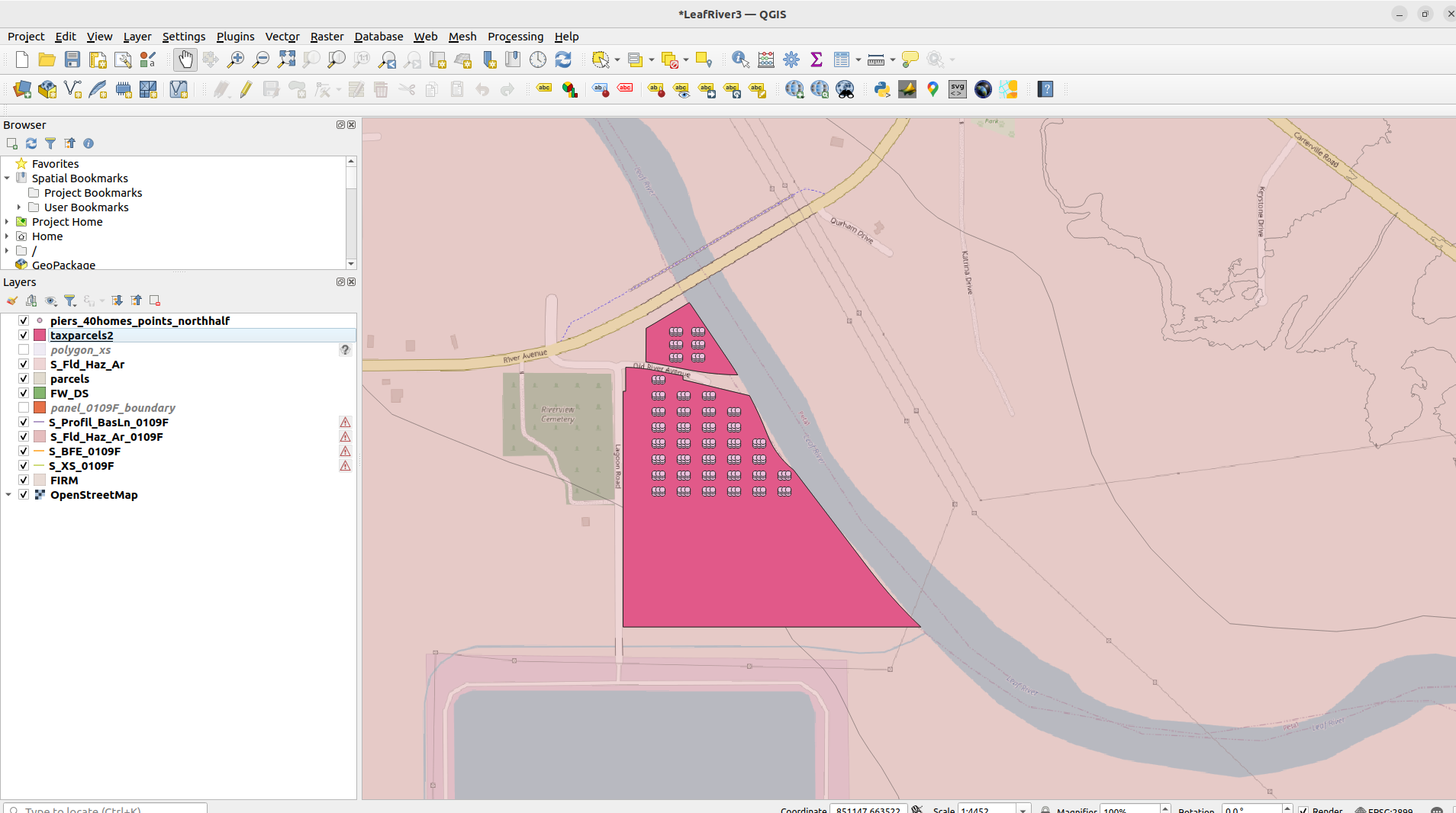

Nurses Oasis (Southwest Corner)

Status: Concept developed

- Location: Southwest corner - not in flood zone

- Access: North-south road on western edge

- Scale: 40 units, 2BR, workforce housing

No flood engineering required. Could move faster than front parcel.

Employer Outreach

Parallel work that informs everything else.

- Conversations with hospitals and employers

- Find out if there's real demand before money gets spent

- The Nurses Oasis concept could adapt for teachers, police, or other groups depending on what we learn

This is about finding customers and understanding need - not construction risk.

Construction Approach

Current thinking: Container vendors charge $90K+ delivered. At that price, the proforma doesn't work for Hattiesburg rents.

Building containers on-site at ~$60K makes the numbers work. It's not complicated - steel boxes with standard residential systems inside. We'd need one person with container construction experience to lead the work.

We won't build for half what vendors charge, but we can get it low enough to make the project work while still delivering nice housing.

| Track | Waiting On |

|---|---|

| Front Parcel | Jill's HEC-RAS (January) |

| Nurses Oasis | Owner decision, utility investigation |

| Employer Outreach | Nothing - can happen anytime |

| Container Capability | Finding the right person |

The workforce housing concept adapts based on what we learn:

- Nurses: Forrest General is the obvious first conversation

- Teachers: Different amenities, similar income profile

- Police/Fire: Shift workers with similar needs

- University: Faculty, graduate students

We start with nurses because hospitals are the clearest target, but the model works for other groups.

Key question: Are utilities available in the N-S road right-of-way?

| If YES | Infrastructure cost for Nurses Oasis drops significantly |

| If NO | Need to factor in utility extension |

This affects the proforma and needs investigation.

4. Housing Strategy

Workforce housing for essential workers - starting with nurses.

See Section 7 for full proforma →

Why Nurses?

Nurses aren't broke. They can afford quality housing - the market just isn't building it for them.

| Hattiesburg RN Income | Annual | Monthly |

|---|---|---|

| New Graduate | $65,000 | $5,420 |

| Average RN | $72,000 | $6,000 |

| Experienced | $85,000 | $7,080 |

The Gap = Our Opportunity. Premium housing at $1,350/month is well within reach.

Hospital shift workers have specific housing requirements:

- Blackout curtains - mandatory for night shift sleep

- Quiet environment - soundproofing, no noisy neighbors

- Bathroom NOT through bedroom - different shift roommates

- In-unit washer/dryer - can't haul scrubs after 12-hour shift

- Short commute - under 15-20 minutes to hospital

- Secure, well-lit parking - night shift returns at odd hours

- Pet-friendly - big differentiator in this market

The river trail becomes an amenity - walking/jogging path with park at water's edge.

This isn't a survey - it's phone calls with a specific proposal.

Call HR departments and ask:

- "Are your nurses having trouble finding housing near the hospital?"

- "What's the commute situation for your shift workers?"

- "Have you looked at any housing partnership programs?"

- "If someone built housing 10 minutes from hospital with features designed for 12-hour shift workers, would that help recruiting?"

Target Contacts:

| Forrest General Hospital | 3,100+ employees, many shift workers |

| University of Southern Miss | Faculty, staff, graduate students |

| Camp Shelby | Civilian workers, visiting personnel |

| William Carey University | Faculty and student housing needs |

If hospitals are interested, we adapt the concept. If teachers or police show more demand, we pivot. The model works for any essential worker group.

Construction Approach

The math only works if we control construction costs.

We need to build them ourselves.

The Problem: Buying container homes retail means paying for:

- Vendor's design costs

- Vendor's fabrication overhead

- Vendor's profit margin (30-40%)

- Transportation from wherever they build

That adds up to $90K+ per unit. At Hattiesburg rents, the rental math doesn't work.

The Solution: Build like a construction project, not a product purchase.

- Hire ONE experienced person from container factory background

- Buy containers direct ($3-5K each)

- Use local labor for finish work

- Control the process, capture the margin

Container construction isn't complicated - it's steel boxes with standard residential systems inside. The "secret sauce" is just knowing the details, which one experienced person provides.

Target: $60,000 per unit all-in

| Container (40' high-cube) | $4,000 |

| Foundation/setting | $6,000 |

| Openings, framing, insulation | $12,000 |

| MEP (mechanical, electrical, plumbing) | $18,000 |

| Interior finish | $12,000 |

| Exterior/deck/stairs | $8,000 |

| Total | $60,000 |

This is achievable with direct labor and materials control. It's NOT achievable buying finished units from a vendor.

Structural Insulated Panels (SIP) are another option:

- Factory-built panels, assembled on site

- Excellent energy efficiency

- Works well with pier foundations

- Similar cost profile to container build-out

Supplier: Supreme Insulated Panel Systems (Mobile, AL)

Could use SIP for some units, containers for others - mix based on what works.

Owner Decision

Build containers ourselves, use SIP, or hybrid approach?

Either way: we can't make budget paying retail for finished units.

5. Flood Engineering

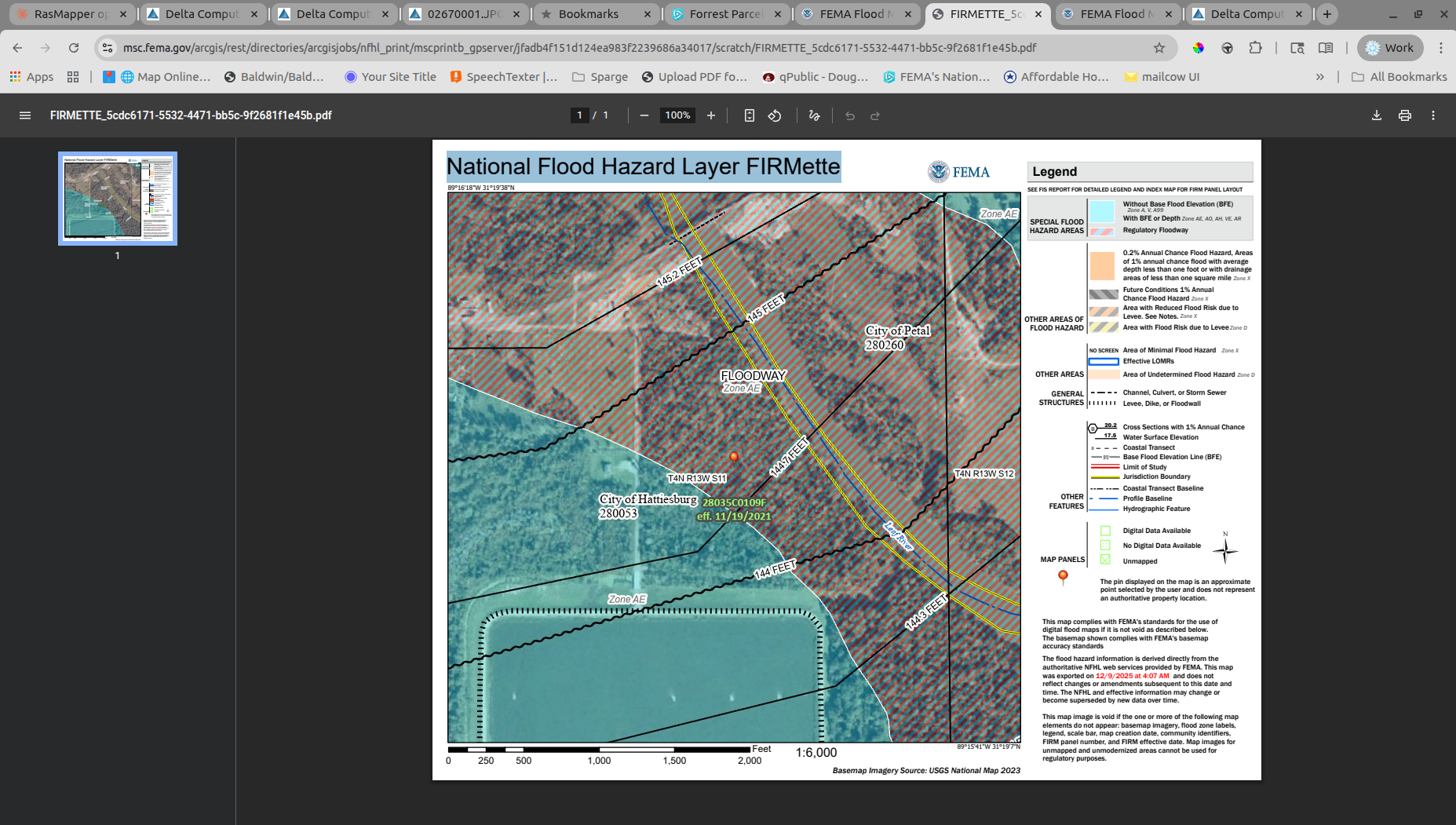

Why No-Rise certification matters (front parcel only).

Front Parcel: Zone AE

Special Flood Hazard Area

Requires piers + No-Rise

More complex

Southwest: No Flood Zone

Standard construction OK

No HEC-RAS needed

Simpler, cheaper

Front parcel along Leaf River is in Zone AE (1% annual flood chance).

Large parcel shows mixed flood zones. Southwest corner is clear.

FEMA Requirement: 44 CFR 60.3(d)(3)

Development in floodway must show ZERO increase in flood levels.

- Engineer builds HEC-RAS model of existing conditions

- Add proposed structures (piers) to model

- Compare water surface elevations

- If no increase → PE certifies No-Rise

12" circular piers create minimal obstruction to flood flow.

This makes No-Rise certification achievable.

Engineer: Jill (hydraulic engineer)

Status: Phase 1 modeling contracted

Expected: January 2025

Required for front parcel. NOT required for southwest corner.

6. Stakeholder Survey

Create buzz by asking questions - costs nothing but time.

Who to Survey

| Organization | Why | Contact |

|---|---|---|

| Univ. Southern Miss | 14,500 students, faculty needs | Housing Office, HR |

| Forrest General Hospital | 3,100 employees, shift workers | HR Director |

| Camp Shelby | Transient personnel, families | Housing Office |

| William Carey Univ. | Student/faculty housing | Housing Office |

| Housing Authority | Waitlist insight, partnerships | Executive Director |

Subject: New Workforce Housing on Leaf River - What Would You Want?

- Do your employees struggle to find affordable housing?

- What unit sizes are most needed? (studio, 1BR, 2BR, 3BR)

- What rent range is realistic for your workforce?

- Would waterfront location be attractive?

- Any interest in employer housing partnerships?

- Would you help spread the word when units are available?

"We're in early planning and want to build what the community needs."

- Unit mix: What sizes actually needed

- Price point: What rents market supports

- Demand signals: Who's interested before we build

- Partnerships: Employer housing programs

- Marketing: Who will spread the word

Just by asking, you create awareness:

- "New development coming on the Leaf River"

- "They're actually asking what people need"

- "Waterfront housing in Hattiesburg"

By groundbreaking, you have a waiting list.

Owner Decision

Conduct stakeholder outreach before finalizing plans?

7. Budget

Pre-development costs and pro forma by component.

Pre-development budget, construction methodology, and financial projections for each development component.

8. Next Steps

Development components and typical process.

Development Components

This property supports three development components.

5.2 acres outside the flood zone. Southwest corner. Fewest regulatory constraints.

| Location | Southwest corner, along existing north-south road |

| Buildable area | ~5.2 acres |

| Flood zone | Outside Special Flood Hazard Area |

| Housing type | Prefab homes, 15-25 units |

| Target market | Healthcare workers, essential employees |

Existing road access. Standard permitting path.

Highway frontage along US-98. Boat ramp, restaurant or retail, some residential.

| Location | Front parcel, river frontage |

| Flood zone | Zone AE and Floodway |

| Potential uses | Boat ramp, restaurant, retail, residential |

| Status | Feasibility depends on flood zone analysis in progress |

No-Rise certification required for Floodway construction.

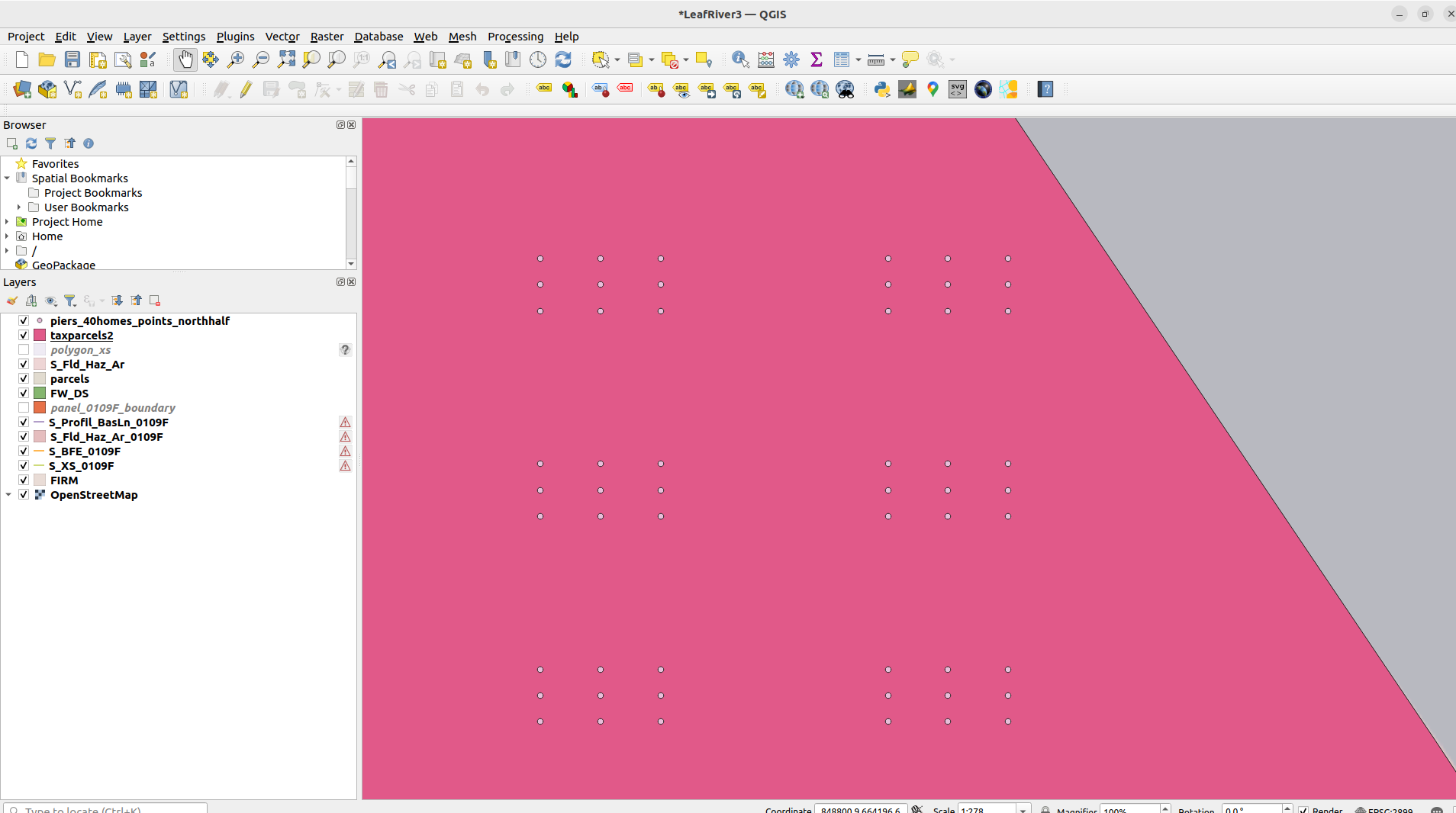

North half of the property. Approximately 30 additional home sites.

| Location | North half of property |

| Capacity | ~30 home sites |

| Timing | Depends on earlier phases |

How Development Proceeds

Typical sequence for residential development in Hattiesburg.

Civil engineer reviews site constraints.

Scope typically includes:

- Flood zone boundaries and elevation requirements

- Utility availability (water, sewer, electric)

- Access and road requirements

- Zoning classification and allowed uses

- Any site-specific constraints

Materials for pre-application review.

- Architectural renderings (exterior views)

- Site concept plan (layout, access, setbacks)

- Project narrative

These materials communicate the development concept to planning staff.

Informal review with City planning staff.

Hattiesburg offers pre-application meetings to discuss proposed developments before formal submission. The meeting covers:

- Zoning requirements

- Site plan expectations

- Potential issues or conditions

- Required approvals and timeline

Resources

Submittal for required approvals.

Based on pre-application feedback:

- Site Plan Review application

- Required drawings and documentation

- Planning Commission review (if required)

- Building permits

Timeline from pre-application to building permit is typically 3-6 months.

Phased approach, building in clusters.

The Oasis layout supports phased construction:

- Build in clusters of 1-3 units

- Each phase can proceed independently

- Scale based on market absorption

Pre-Development Investment

Professional preparation requires capital before construction begins.

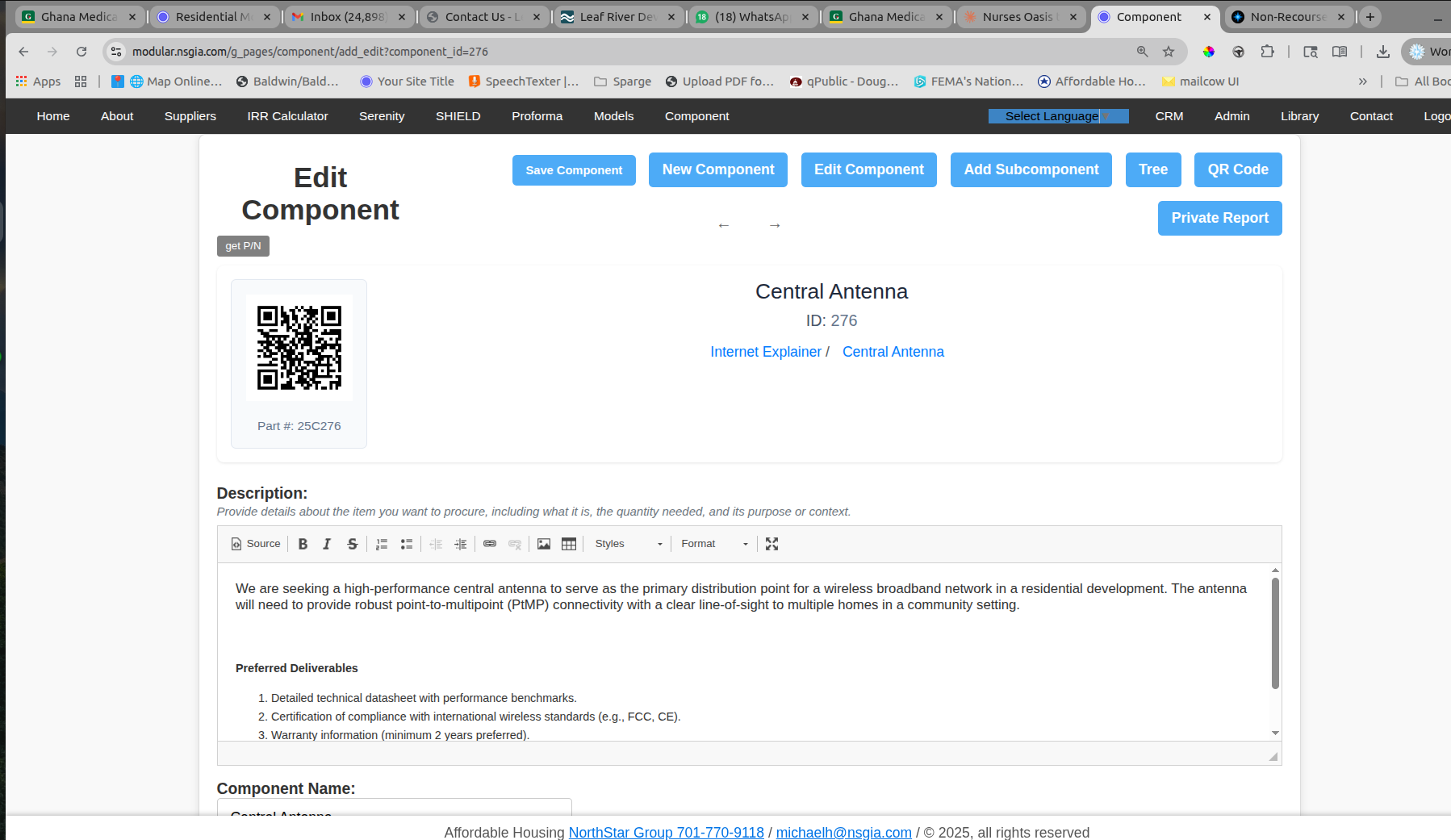

9. Cost Analysis System

Proprietary procurement and modeling platform.

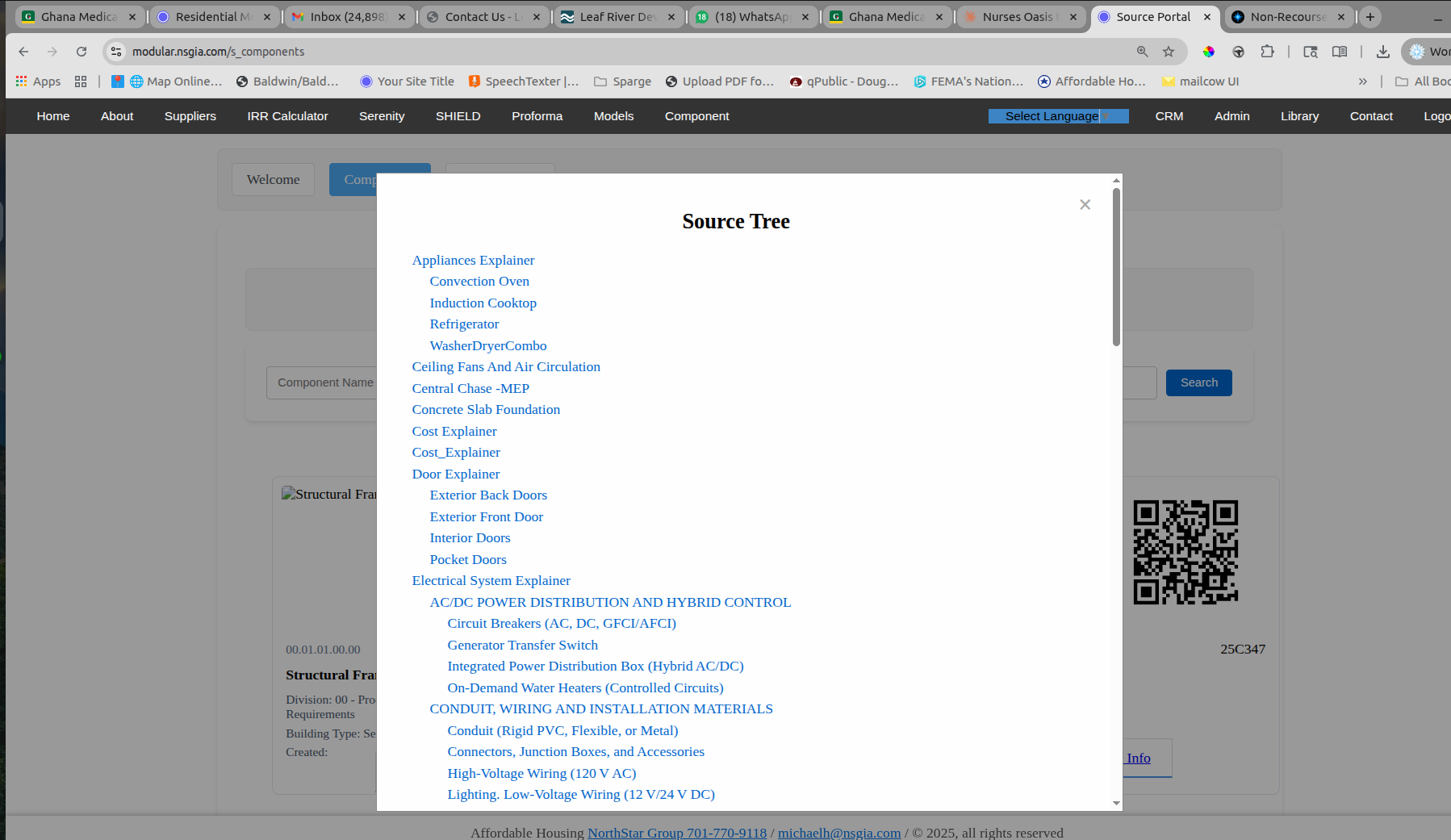

Every item in a build is tracked as a component with full specifications.

Each component record includes:

- Specifications and requirements

- Qualified vendors and pricing

- Installation instructions

- Maintenance procedures

After initial qualification, sourcing becomes automatic. The system knows what to order, from whom, at what price.

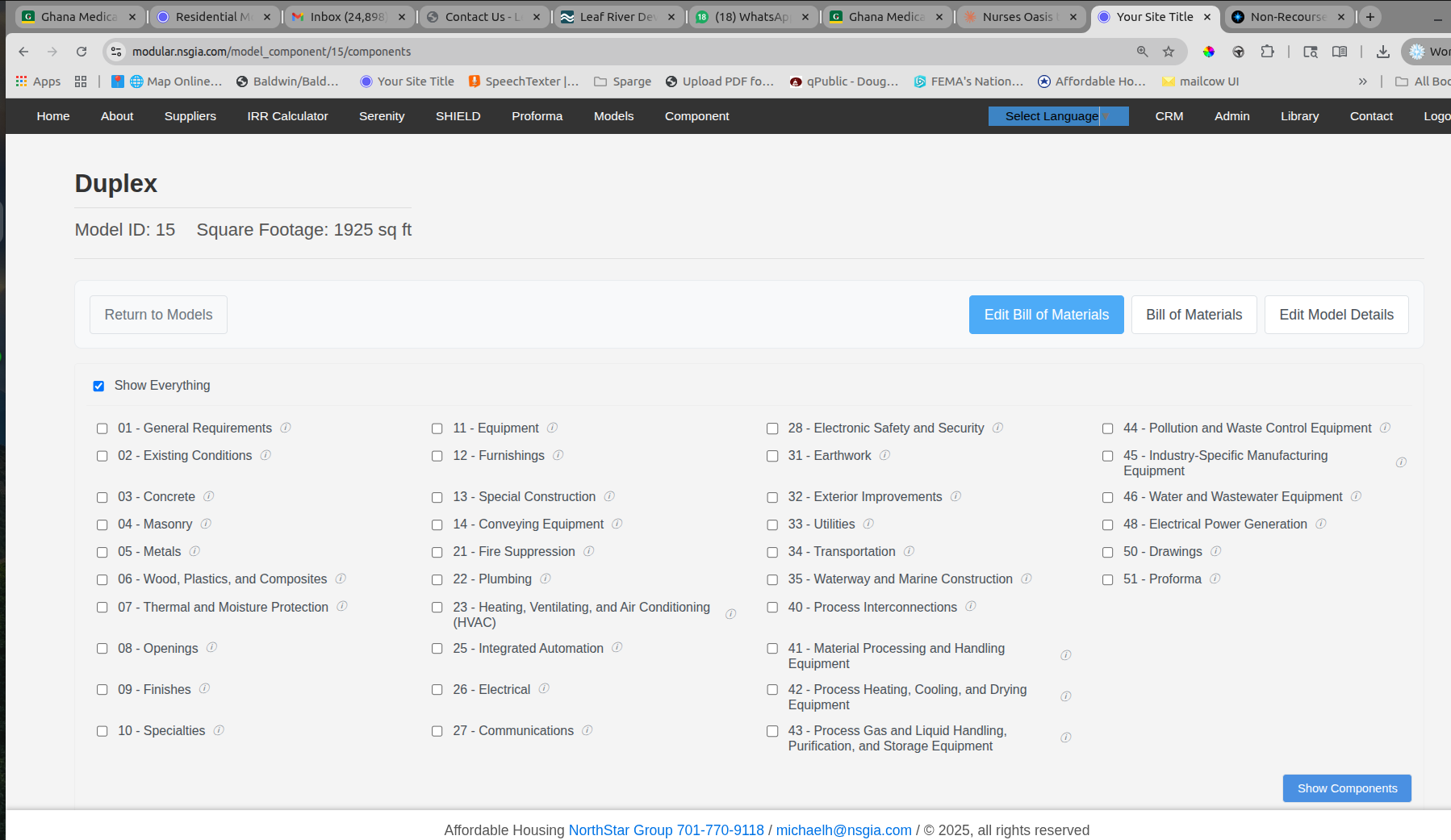

Components roll up into assemblies. Assemblies roll up into models.

A door assembly includes the door, frame, hardware, weatherstripping, and installation labor. The system tracks all of it as a unit.

This structure allows accurate cost rollups at any level — component, assembly, or complete model.

Each home type gets full cost modeling before construction.

The bill of materials for a model includes every component and assembly required. Pricing updates automatically as vendor quotes change.

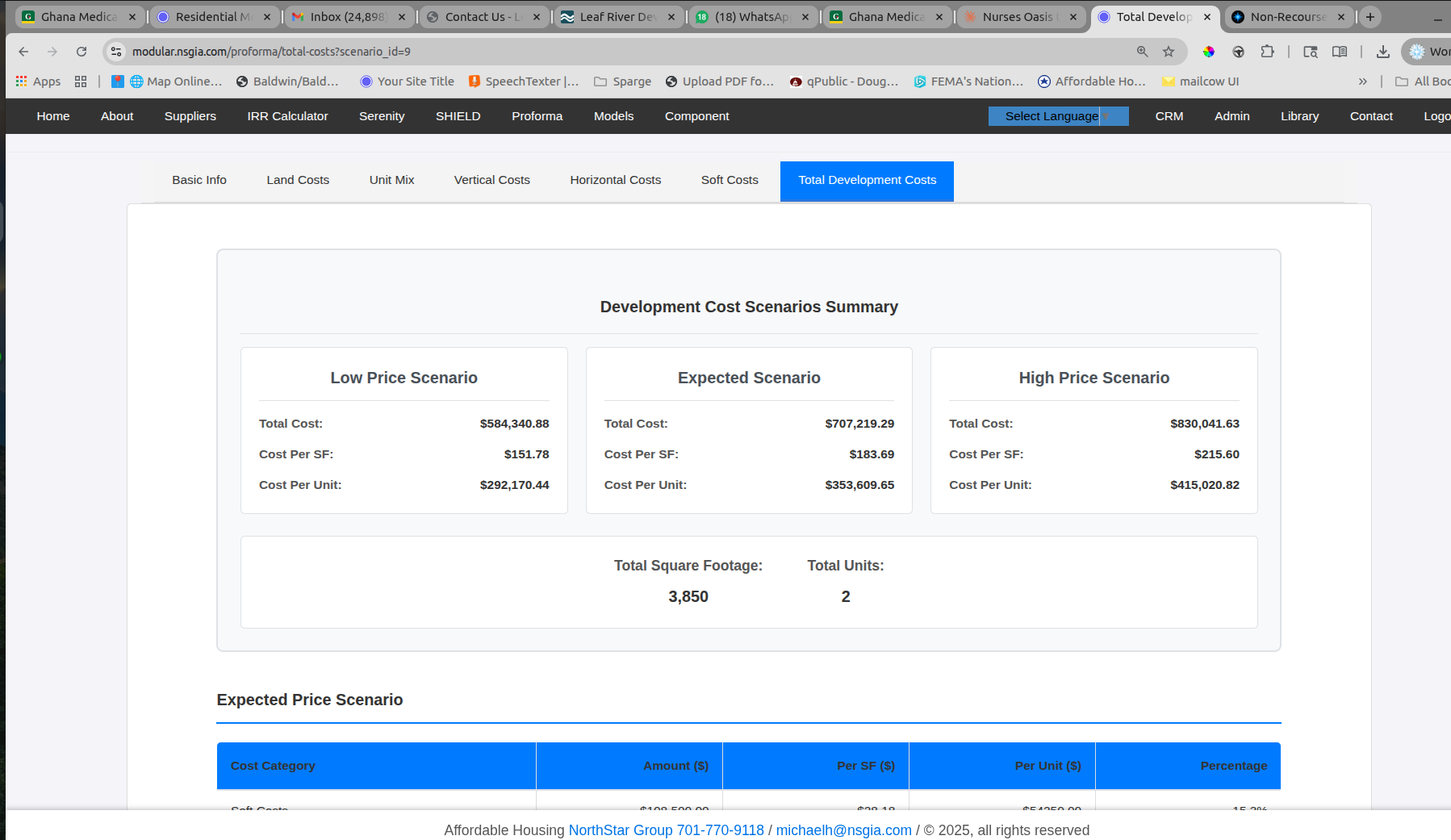

Full pro forma analysis with low/expected/high scenarios.

The system calculates total development costs across all units, with per-unit and per-square-foot breakdowns.

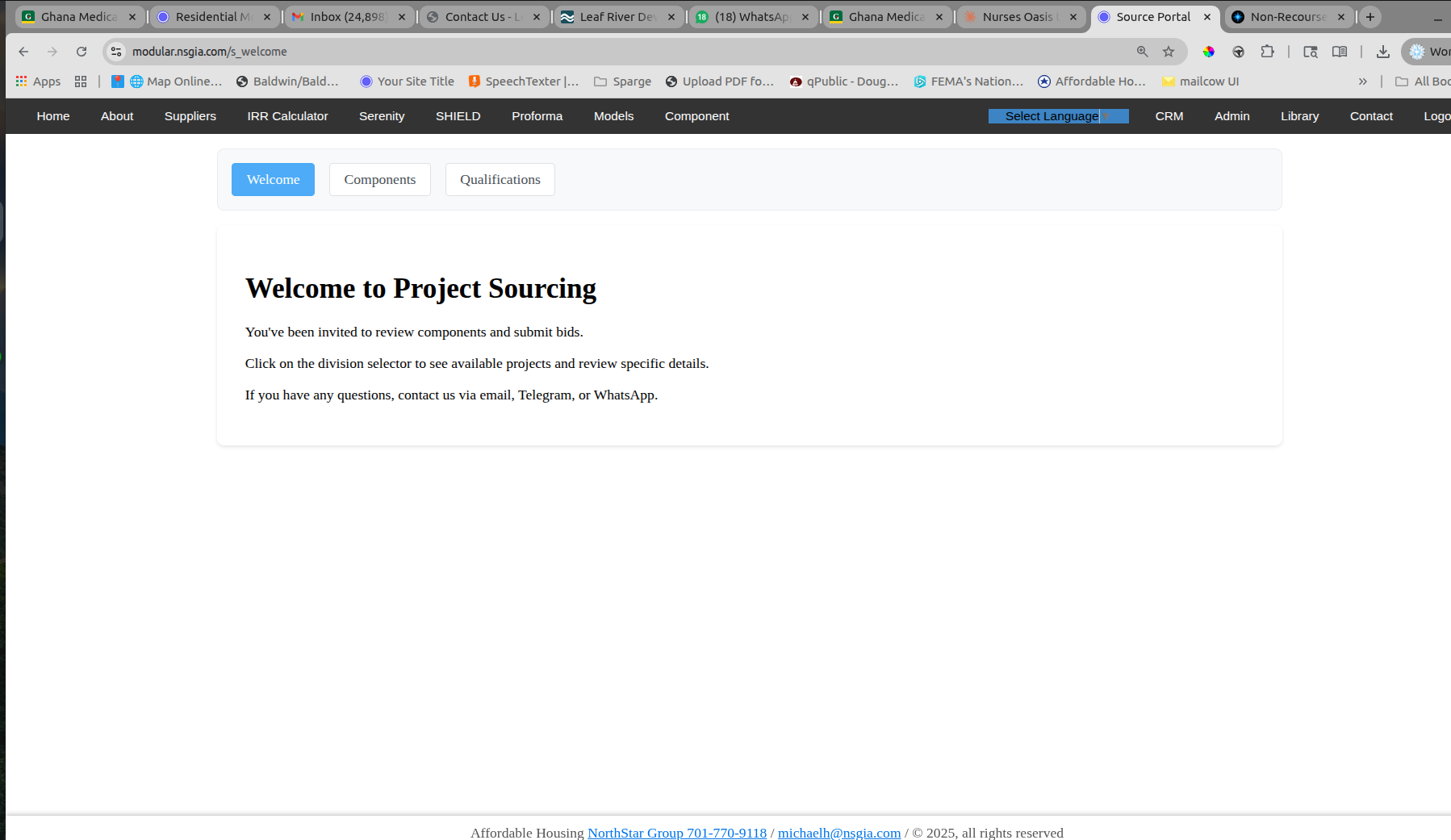

Vendors can self-serve to review components and submit bids.

This creates competitive pricing without manual quote collection. Vendors see specifications and submit pricing directly into the system.

The system generates directive reports for each trade.

A framing report tells the framer exactly what to do — materials list, cut dimensions, installation sequence. No ambiguity, no interpretation required.

This allows skilled workers to execute efficiently without constant supervision.

The alternative is handing a materials list to a big-box store and letting them fill it.

Problems with that approach:

- Selection controlled by the retailer, not the builder

- No visibility into substitutions or quality variations

- Markup built into every item

- No institutional memory — start over every project

The component system provides:

- Quality control at the specification level

- Transparent pricing from multiple vendors

- Repeatable processes that improve over time

- Documentation that survives personnel changes